APC TECHNOLOGY HAS OVER 30 YEARS OF EXPERIENCE DESIGNING AND MANUFACTURING RUGGED ELECTRONIC SOLUTIONS CAPABLE OF ENDURING AND OPERATING IN THE HARSH ENVIRONMENTS OF THE FOOD AND BEVERAGE INDUSTRY. WITH THOUSAND OF FOOD-GRADE UNITS IN USE ACROSS AUSTRALIA AND OVERSEAS, WE CAN ENGINEER A SOLUTION TO FIT YOUR REQUIREMENTS.

We offer unrivalled experience and capabilities to design, manufacture, test and support a product that seamlessly integrates into the existing infrastructure. We work closely with our clients to understand their needs and deliver a product that exceeds expectations.

Expertise

Designed and manufactured to protection standard IP66, our F&B solutions are fully sealed, rated to +60° C and available with sealed connectors eliminating all gaps and surface collection points. This prevents the build-up of debris and waste, making our rugged computing equipment the ideal solution for hot wash applications with industry-standard cleaning agents.

- Abattoirs

- Meat processing

- Dairy processing

- Food preparation and packaging

- Fish processing

- Cold stores operation

- Wineries

- Bottling

Solutions

Every technology solution we prototype, engineer, test and maintain is unique, designed for the specific needs and requirements of our food and beverage clients. Some of our F&B-ready solutions include:

- Fully enclosed IP66 touchscreen PCs and displays

- Panel mount touch screen PCs and displays

- Workstations

- Industrial-grade fanless PC’s

- Rugged mobile tablet and laptop

- Food-grade rugged keyboards and pointers

- Accessories: mounts, pedestals & keyboard trays

- Hazardous area PCs, tablets, keyboards and pointers

- Printer & server cabinets

About the food manufacturing process

Food and beverage manufacturers must remain ahead in their field, and the operational efficiency of their plants and factories is a critical factor. Food and beverage technology can assist with optimising efficiencies to support the success of the business.

Today’s operations managers are facing a plethora of pressures. Aside from increasing costs, other areas of focus are the continual demand for increased operational efficiency and throughput without compromising hygiene, food safety and product quality.

APC Technology can collaborate with your organisation to design, manufacture or supply complete end-of-the-line food processing and packaging solutions to automate industry operations and improve your bottom line. From prototyping, testing, and manufacture to maintenance, we provide a wide range of services to assist in the design and commissioning of food technology equipment.

-

GETAC F110

SKU 00000AU$0.00Buy Now -

Getac 360 Pro - Military grade fully rugged Laptop computer

SKU 00184AU$0.00Buy Now -

Getac S410 Laptop (G5)

SKU 00185AU$0.00Buy Now -

Nexcom 19" Industrial Display

SKU 00190AU$0.00Buy Now -

APC Technology - Display with optional Touchscreen CT Series

SKU 00192AU$0.00Buy Now -

Nexcom VTC 7260-x Fanless AI-aided Vehicle Computer

SKU 00173AU$0.00Buy Now -

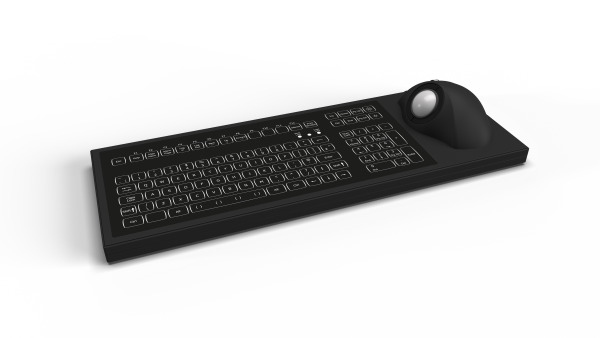

NSI Backlit waterproof keyboard with E38 ergonomic trackball - Desktop

SKU 00064AU$0.00Buy Now -

NSI Backlit sealed keyboard with trackball - panel mount

SKU 00072AU$0.00Buy Now -

NSI Backlit keyboard with ergonomic trackball - panel mount

SKU 00073AU$0.00Buy Now -

NSI Backlit compact keyboard with trackball - panel mount

SKU 00081AU$0.00Buy Now -

NSI Backlit compact keyboard with trackball - desktop

SKU 00095AU$0.00Buy Now -

NSI Food keyboard with touchpad

SKU 00098AU$0.00Buy Now -

NSI Membrane IP65 keyboard with trackball - desktop

SKU 00099AU$0.00Buy Now -

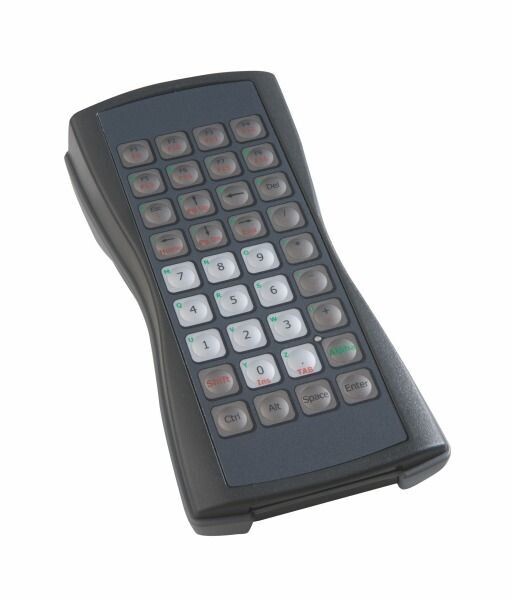

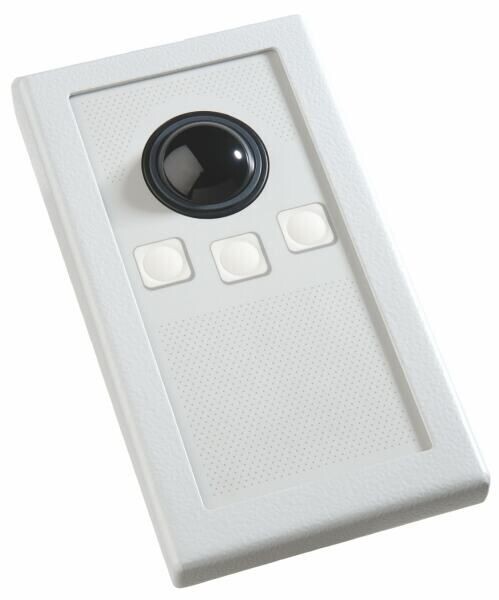

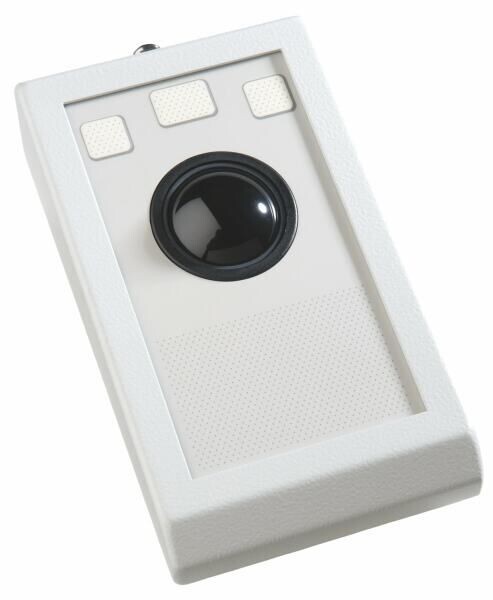

NSI Handheld desktop keyboard

SKU 00100AU$0.00Buy Now -

NSI Numpad and function keyboard - desktop

SKU 00101AU$0.00Buy Now -

NSI Membrane IP65 keyboard with trackpad - desktop

SKU 00102AU$0.00Buy Now -

NSI Industrial IP65 keyboard with trackball

SKU 00103AU$0.00Buy Now -

NSI Industrial IP65 keyboard with touchpad

SKU 00104AU$0.00Buy Now -

NSI Backlit sealed keyboard with trackball - desktop

SKU 00105AU$0.00Buy Now -

NSI Compact industrial desktop keyboard

SKU 00106AU$0.00Buy Now -

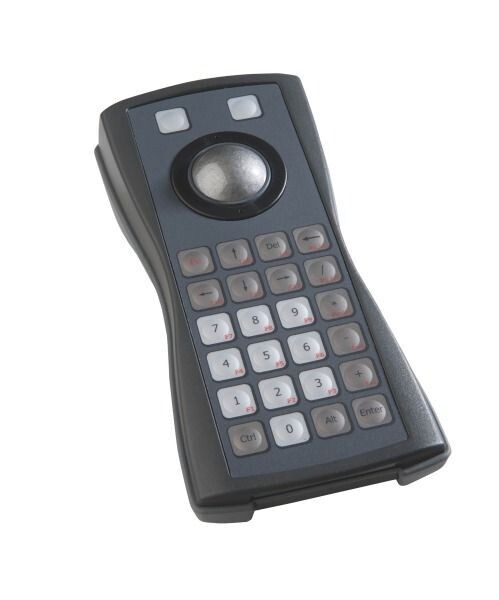

NSI Handheld desktop keyboard with trackball

SKU 00107AU$0.00Buy Now -

NSI Backlit numpad keyboard - desktop

SKU 00108AU$0.00Buy Now -

NSI Backlit keyboard with ergonomic trackball - desktop

SKU 00109AU$0.00Buy Now -

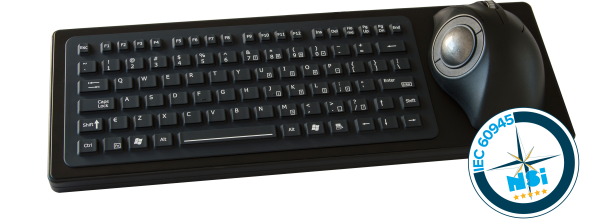

NSI IEC60945 silicone keyboard with ergonomic trackball - desktop

SKU 00110AU$0.00Buy Now -

NSI IEC60945 marine silicone rubber keyboard - desktop

SKU 00111AU$0.00Buy Now -

NSI IEC60945 marine waterproof ECS keyboard - desktop

SKU 00112AU$0.00Buy Now -

NSI IEC60945 marine keyboard with 50 mm ergonomical trackball - desktop

SKU 00113AU$0.00Buy Now -

NSI IEC6094 marine ECDIS keyboard - desktop

SKU 00114AU$0.00Buy Now -

NSI IEC60945 compact silicone rubber keyboard - desktop

SKU 00115AU$0.00Buy Now -

NSI IEC60945 marine backlit keyboard - desktop

SKU 00117AU$0.00Buy Now -

NSI Ergonomical 38 mm desktop trackball

SKU 00118AU$0.00Buy Now -

NSI Ergonomical 38 mm panel mount trackballs

SKU 00119AU$0.00Buy Now -

NSI Sealed IP68 trackball

SKU 00120AU$0.00Buy Now -

NSI Industrial waterproof panel mount trackballs

SKU 00121AU$0.00Buy Now -

NSI Trackball with backlit Halo ring

SKU 00122AU$0.00Buy Now -

NSI Compact IP68 trackball with scroll wheel

SKU 00123AU$0.00Buy Now -

NSI Industrial IP67 trackball

SKU 00124AU$0.00Buy Now -

NSI IP68 trackball with scroll wheel

SKU 00125AU$0.00Buy Now -

NSI Trackball with backlighting

SKU 00126AU$0.00Buy Now -

NSI Ergonomical 50 mm panel mount trackball

SKU 00127AU$0.00Buy Now -

NSI Stainless steel 50 mm trackball

SKU 00128AU$0.00Buy Now -

NSI Stainless steel 38 mm trackball

SKU 00129AU$0.00Buy Now -

NSI Stainless steel 25 mm trackball

SKU 00130AU$0.00Buy Now -

NSI Vandalproof 50 mm trackball

SKU 00131AU$0.00Buy Now -

NSI Ergonomical 50 mm desktop trackball

SKU 00132AU$0.00Buy Now -

NSI Vandalproof 25 mm trackball

SKU 00133AU$0.00Buy Now -

NSI Vandalproof 38 mm trackball

SKU 00134AU$0.00Buy Now -

NSI LED Backlit stainless steel trackball

SKU 00135AU$0.00Buy Now -

NSI Self-draining trackball

SKU 00136AU$0.00Buy Now -

NSI Industrial waterproof desktop trackball

SKU 00137AU$0.00Buy Now -

NSI IP65 sealed 38 mm panel mount trackball

SKU 00138AU$0.00Buy Now -

NSI IP65 sealed 38 mm desktop trackball

SKU 00139AU$0.00Buy Now -

NSI IP65 sealed 50 mm desktop trackball

SKU 00140AU$0.00Buy Now -

NSI IEC60945 marine waterproof trackball

SKU 00141AU$0.00Buy Now -

NSI IEC60945 marine ergonomic 38 mm trackballs - desktop

SKU 00142AU$0.00Buy Now -

NSI IEC60945 marine ergonomic 38 mm trackballs - panel mount

SKU 00143AU$0.00Buy Now -

NSI IEC60945 marine compact trackball with scroll wheel

SKU 00144AU$0.00Buy Now -

NSI IEC60945 marine ergonomic 50 mm trackballs - desktop

SKU 00145AU$0.00Buy Now -

NSI IEC60945 marine ergonomic 50 mm trackballs - panel mount

SKU 00146AU$0.00Buy Now -

NSI IEC60945 marine IP68 trackballs - panel mount

SKU 00147AU$0.00Buy Now -

NSI IEC60945 marine IP68 trackball - desktop

SKU 00148AU$0.00Buy Now -

NSI 50 mm infrared optical trackball module

SKU 00149AU$0.00Buy Now -

NSI Backlit laser OEM trackball module

SKU 00150AU$0.00Buy Now -

NSI 38 mm infrared optical trackball module

SKU 00151AU$0.00Buy Now -

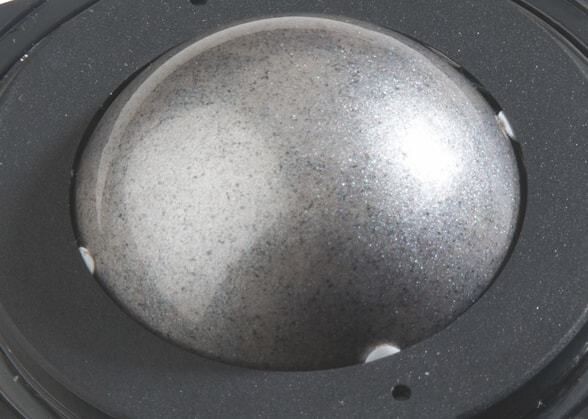

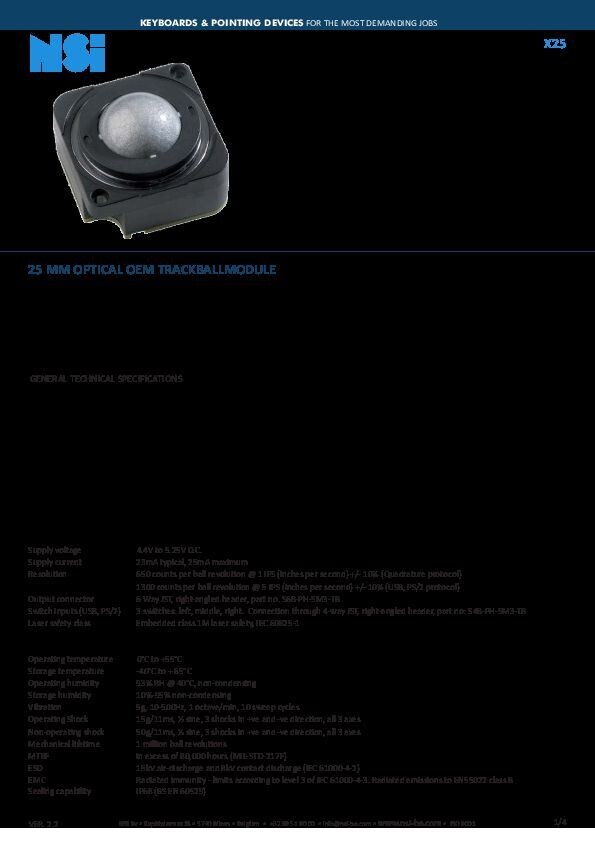

NSI 25 mm laser OEM trackball module

SKU 00152AU$0.00Buy Now -

NSI 19 mm laser OEM trackball module

SKU 00153AU$0.00Buy Now -

NSI 13 mm laser OEM trackball module

SKU 00154AU$0.00Buy Now -

NSI 3 axis trackballs

SKU 00155AU$0.00Buy Now -

NSI 16 mm OEM trackball module

SKU 00156AU$0.00Buy Now -

Sunit WorkBook Q8

SKU 00158AU$0.00Buy Now -

Sunit Workbook Q8a

SKU 00159AU$0.00Buy Now -

Sunit WorkBook Q10

SKU 00160AU$0.00Buy Now -

Sunit WorkBook Q10a

SKU 00161AU$0.00Buy Now -

Sunit 12HD

SKU 00162AU$0.00Buy Now -

Sunit F19

SKU 00163AU$0.00Buy Now -

Sunit F12

SKU 00164AU$0.00Buy Now -

Sunit F10

SKU 00165AU$0.00Buy Now -

Sunit F7

SKU 00166AU$0.00Buy Now -

Sunit F7 Outdoor OB

SKU 00167AU$0.00Buy Now -

NEXCOM NISE 3800E

SKU 00168AU$0.00Buy Now -

iBase BYTEM-103-PC

SKU 00169AU$0.00Buy Now -

Nexcom NISE3900e Fanless Computer

SKU 00181AU$0.00Buy Now -

Nexcom NISE3900e-H310 Fanless Computer

SKU 00182AU$0.00Buy Now -

Nexcom NISE3900E2/P2/P2E

SKU 00183AU$0.00Buy Now -

iBase BYTEM-123-PC

SKU 00170AU$0.00Buy Now -

iBase MPT-1000V

SKU 00171AU$0.00Buy Now -

iBase MPT-3000V

SKU 00172AU$0.00Buy Now -

NSI Food keyboard with trackball

SKU 00097AU$0.00Buy Now -

NSI Compact LED backlit keyboard - desktop

SKU 00096AU$0.00Buy Now -

NSI LED backlit waterproof keyboard - desktop

SKU 00094AU$0.00Buy Now -

NSI Silicone rubber keyboard with trackball - desktop

SKU 00093AU$0.00Buy Now -

NSI IEC6094 marine ECDIS keyboard - panel mount

SKU 00092AU$0.00Buy Now -

NSI IEC60945 compact marine keyboard - panel mount

SKU 00091AU$0.00Buy Now -

NSI IEC60945 marine keyboard - panel mount

SKU 00090AU$0.00Buy Now -

NSI IEC60945 marine silicone rubber keyboard - panel mount

SKU 00089AU$0.00Buy Now -

NSI IEC60945 marine waterproof ECS keyboard - panel mount

SKU 00088AU$0.00Buy Now -

NSI IEC60945 marine backlit keyboard - panel mount

SKU 00087AU$0.00Buy Now -

NSI IEC60945 silicone keyboard with ergonomic trackball

SKU 00086AU$0.00Buy Now

SUNFRESH SALADS

High-Risk Area Food Grade Panel PCs

Sunfresh engaged APC Technology to design and manufacture a food-grade FT panel PC which incorporated custom components to meet their requirements. We delivered customised panel PCs featuring IP66 rating and resistive touchscreens to allow for gloved operations; RJ45 to allow for a hardwire internet connection, and wall mount brackets suitable for refrigerated walls.

Benefits of food manufacturing technology in supply chain management

Integrating food and beverage technology into your automation systems can significantly contribute towards a journey from farm, plant to fork. The food and beverage industry is the crucial link in that process. Gaining a competitive edge in the industry can be achieved through the integration of new manufacturing technologies. Benefits could include :

- Increased output through food tech: Our ruggedised solutions can support a business to increase output through technological improvements with the objective to scale to larger batch production. Food tech also ensures improved food safety and shelf-life, and strict quality control.

- Stay ahead of the competition: The food and beverage industry faces the challenges of stricter product requirements as well as larger volumes at lower prices. Therefore, higher efficiency and labour productivity are a must to remain competitive. Simultaneously, society and consumers are demanding more in terms of sustainability and health. Therefore, digitilisation and integration of cutting-edge automation systems can enable businesses to respond to this demand.

- Increased predictability while mitigating pain points: Digitalisation of your processes can contribute towards streamlined production lines. Moreover, food tech encourages stricter maintenance inspection opportunities.

Contact us

See us in person

991 Port Road

Cheltenham, SA 5014

All Rights Reserved | APC Technology